In the realm of standard CNC machining, a tolerance of ±0.005mm is considered high precision. However, for industries such as aerospace, photonics, and medical device manufacturing, this level of accuracy is merely a starting point. When blueprints demand sub-micron form accuracy and nanometric surface roughness, standard machining fails.

This is the domain of Ultra-Precision Machining (UPM).

For engineers seeking ultra-precision machining services, the choice often boils down to two distinct but related technologies: Single Point Diamond Turning (SPDT) and Ultra-Precision Milling (Micro-Milling). While both utilize natural or synthetic diamond tools to achieve mirror-like finishes, they employ fundamentally different kinematics.

Understanding the nuance between these two processes is critical. The wrong choice can result in excessive cycle times, unmanageable costs, or surface artifacts that compromise optical performance. This guide provides a technical breakdown of surface integrity, material compatibility, geometric freedom, and cost efficiency to help you select the right manufacturing route.

1. Defining the Technologies: Kinematics Matter

To understand the surface finish and geometric capabilities of each process, we must first look at how the tool interacts with the workpiece.

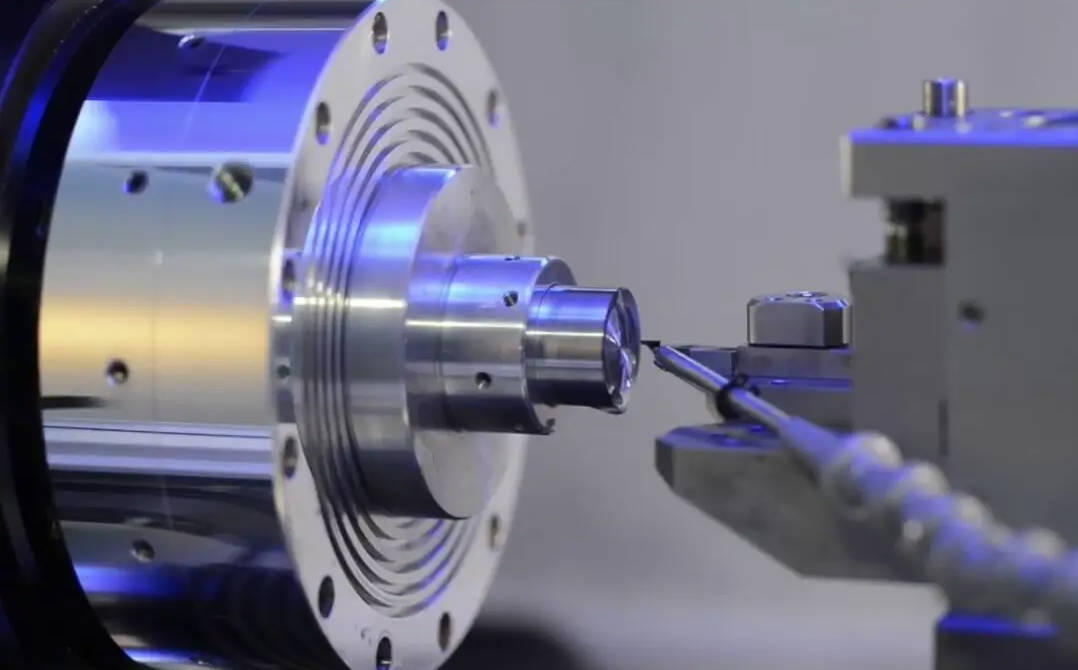

Single Point Diamond Turning (SPDT)

SPDT is essentially an ultra-precise lathe operation. The workpiece is mounted on an air-bearing spindle that rotates at high velocities, while a stationary, monocrystalline diamond tool translates across the surface.

- Kinematics: Workpiece rotates; Tool is stationary (mostly).

- Primary Application: Rotationally symmetric parts.

- The Physics: Because the tool is in constant contact with the material, the cutting force is continuous. This stability allows for the highest possible surface quality.

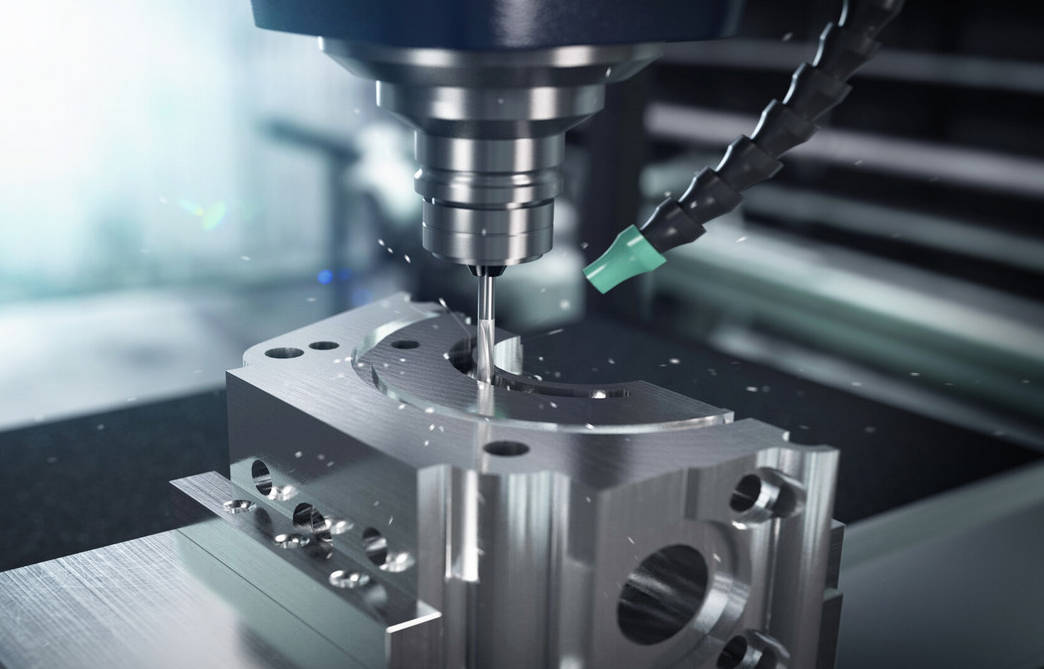

Ultra-Precision Milling (UP Milling)

UP Milling (or Micro-Milling) operates on the principle of a milling machine. A diamond tool (often a fly-cutter or a ball-nose micro-mill) rotates at extremely high RPM (often 40,000 to 100,000+ RPM) on an air-bearing spindle, while the workpiece translates along the X, Y, and Z axes.

- Kinematics: Tool rotates; Workpiece translates.

- Primary Application: Freeform surfaces, non-circular shapes, and micro-structures.

- The Physics: The cutting is interrupted. The tool enters and exits the material thousands of times per second, which introduces dynamic forces that must be strictly controlled to prevent vibration marks.

2. Comparison Point 1: Surface Finish and Optical Quality

For most clients seeking ultra-precision services, surface finish—specifically $R_a$ (Average Roughness)—is the primary KPI.

The SPDT Advantage: The Spiral of Perfection

Single Point Diamond Turning is widely considered the gold standard for optical surface finishes. Because the cutting action is continuous, there are no “entry/exit” shock waves on the surface.

- Achievable Finish: $R_a < 2nm$ to $5nm$ is standard for aluminum and copper.

- Visual Characteristic: Under magnification, an SPDT surface exhibits a diffraction grating effect—a nanometric spiral groove created by the feed rate of the tool. To the naked eye, this appears as a perfect, rainbow-colored mirror.

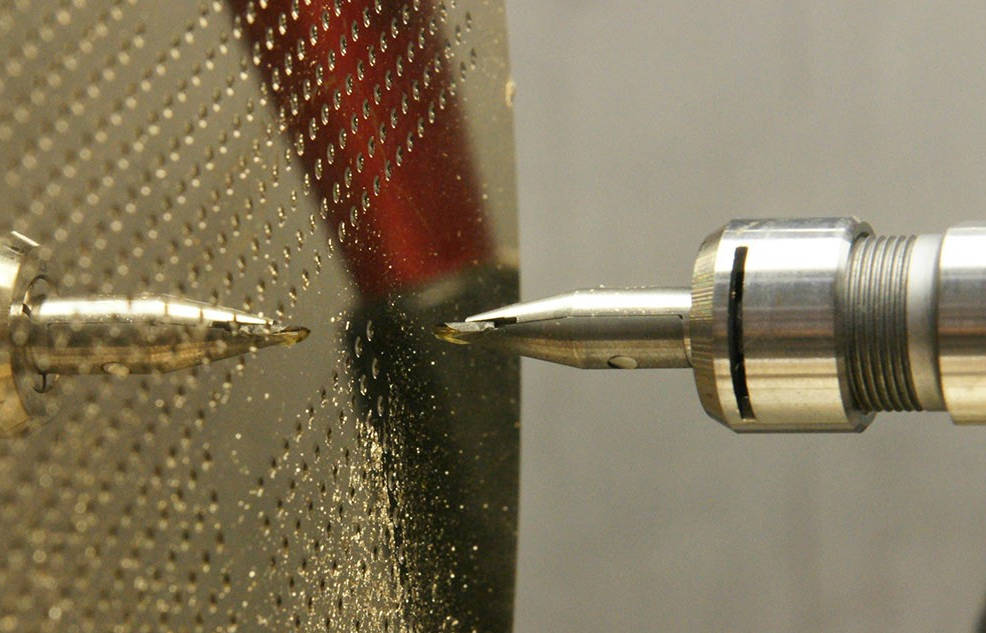

The UP Milling Challenge: Controlling Cusp Heights

Achieving an optical finish with milling is significantly more difficult due to the geometry of the cut. As a ball-nose end mill moves across a surface (raster scanning), it leaves behind tiny peaks of material between passes, known as “cusp heights” or “scallops.”

- Achievable Finish: $R_a < 10nm$ to $20nm$ is achievable but requires aggressive optimization.

- The Trade-off: To reduce the cusp height to an optical level (invisible to the naked eye), the “step-over” (the distance the tool moves sideways for the next cut) must be microscopic—often less than 2 microns. This drastically increases cycle time.

- Visual Characteristic: A milled surface will often show a linear or cross-hatched sheen rather than the perfect radial symmetry of a turned part.

Snippet for Google: When absolute lowest surface roughness ($R_a < 5nm$) is required for mirrors or lenses, Single Point Diamond Turning (SPDT) is the superior choice due to its continuous cutting action. Ultra-Precision Milling is capable of optical finishes but requires significantly longer cycle times to minimize cusp heights.

3. Comparison Point 2: Geometric Freedom

If SPDT offers the best finish, why use UP Milling at all? The answer lies in geometry.

Symmetry vs. Freeform

Diamond Turning is inherently limited to rotationally symmetric shapes—spheres, aspheres, parabolas, and ellipses.

- Note: Advanced SPDT machines equipped with Slow Tool Servo (STS) or Fast Tool Servo (FTS) axes can machine slightly non-symmetrical shapes (like toric lenses or off-axis mirrors) by oscillating the tool hundreds of times per revolution. However, this has limitations regarding the amplitude of the non-symmetry.

Ultra-Precision Milling offers true 3D freedom. It uses 3, 4, or 5-axis interpolation to machine:

- Micro-Lens Arrays (MLA): Hundreds of tiny lenses on a single flat substrate.

- Waveguides: Complex, non-circular optical paths for AR/VR devices.

- Corner Cube Retroreflectors: Geometries with sharp, non-rotational transitions.

Edge Effects and Interrupted Cuts

Diamond tools are incredibly hard but brittle. In SPDT, an “interrupted cut” (like turning a part with holes or slots in it) can be catastrophic. The shock of hitting the gap can chip the diamond edge.

UP Milling excels here. Since milling is inherently an interrupted cut process, the tools and strategies are designed to handle edges and discontinuous features without catastrophic tool failure.

4. Comparison Point 3: Material Compatibility

Both processes rely on monocrystalline diamond tools. Therefore, they share the same fundamental material restrictions. When sourcing ultra-precision machining services, you are generally limited to the “Diamond-Turnable” list.

The “Ideal” Materials

Both SPDT and UP Milling perform exceptionally well with:

- Non-Ferrous Metals: Aluminum (6061, 7075-T6), Oxygen-Free High Conductivity Copper (OFHC), Brass, Tin, and Gold.

- Polymers: PMMA (Acrylic), Polycarbonate, Zeonex/Zeonor (Cyclo Olefin Polymer).

- IR Crystals: Germanium, Zinc Selenide (ZnSe), Silicon, and Calcium Fluoride.

The “Ferrous” Limitation

Why can’t we diamond turn steel or titanium?

Ferrous materials (Iron, Steel, Stainless Steel) have a high chemical affinity for carbon. At the high temperatures generated at the cutting tip, the carbon atoms in the diamond tool chemically react with the iron in the workpiece. This causes “graphitization,” where the diamond tool effectively reverts to graphite and wears away in seconds.

The Solution for Steel Parts: If you need a steel part with an optical finish, the standard workflow is:

- CNC Machine the steel substrate to near-net shape.

- Plate the steel with Electroless Nickel (High Phosphorus).

- Diamond Turn or Micro-Mill the Electroless Nickel layer.

Electroless Nickel is perfectly diamond-turnable and provides the hardness of steel with the optical finish of a soft metal.

Snippet for Google: Neither Diamond Turning nor Ultra-Precision Milling is suitable for directly machining steel or glass. These processes are optimized for non-ferrous metals (Aluminum, Copper), plastics (PMMA), and crystals (Germanium). To machine steel, the part must first be plated with Electroless Nickel.

5. Comparison Point 4: Cost and Cycle Time Analysi

For procurement managers, cost is often the deciding factor. The kinematics of the machines lead to massive differences in cycle time depending on the part geometry.

Efficiency of SPDT (Turning)

Diamond turning is highly efficient. The tool is cutting 100% of the time (or close to it).

- Scenario: Manufacturing a 50mm diameter aluminum aspheric mirror.

- Time: Minutes.

- Cost: Low to Medium.

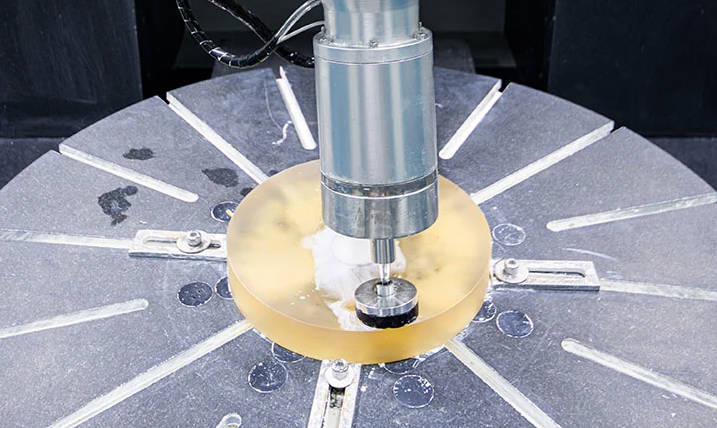

Efficiency of UP Milling (Rastering)

Raster fly-cutting or micro-milling is inherently slower for large surface areas. To achieve a mirror finish, the tool must scan back and forth millions of times with a microscopic step-over.

- Scenario: Manufacturing a 50mm x 50mm flat mirror using milling.

- Time: Hours. (The tool must travel kilometers of linear distance to cover that area with a 2-micron step-over).

- Cost: High.

The “Freeform” Factor

However, price comparisons flip when the geometry becomes complex. If you need a monolithic lens array, SPDT is physically incapable of making it (without extreme STS limitations). You would have to turn individual lenses and assemble them—a nightmare for tolerance stacking.

UP Milling produces the array in one piece. While the machining time is high, it eliminates assembly costs and alignment errors, making it the only viable economic choice for such parts.

6. Summary Table: Quick Reference for Engineers

Below is a direct comparison to help you navigate your RFQ (Request for Quote) process.

| Feature | Single Point Diamond Turning (SPDT) | Ultra-Precision Milling (UP Milling) |

| Primary Kinematics | Lathe (Part rotates) | Mill (Tool rotates) |

| Typical Surface Roughness ($R_a$) | < 2 nm – 5 nm (Best Possible) | < 10 nm – 20 nm (Excellent) |

| Form Accuracy (PV) | < 0.1 $\mu m$ | < 0.3 $\mu m$ – 0.5 $\mu m$ |

| Geometric Capabilities | Rotationally Symmetric (Spheres, Aspheres) | Freeform, Lens Arrays, Raster Surfaces |

| Interrupted Cuts | Difficult (Risk of tool chipping) | Excellent (Designed for interrupted cuts) |

| Relative Cycle Time | Fast (Continuous material removal) | Slow (Raster scanning required) |

| Ideal Applications | Laser mirrors, camera lenses, infrared optics | AR/VR waveguides, lens arrays, micro-molds |

7. Advanced Considerations: The Hybrid Approach

In modern ultra-precision machining services, the line between these two technologies is blurring. High-end 5-Axis Ultra-Precision centers can now perform both operations in a single setup.

For example, a complex optical housing might require:

- Diamond Turning to create the main optical aperture (for maximum speed and surface quality).

- Micro-Milling to create precise alignment datums and non-circular mounting features on the same part.

Using a vendor capable of “Hybrid Ultra-Precision Machining” ensures you get the best of both worlds: the speed/finish of turning and the geometric freedom of milling, without losing accuracy due to re-fixturing.

8. Conclusion: Which Service Do You Need?

The choice between Diamond Turning and Ultra-Precision Milling is rarely a preference—it is usually a dictate of geometry.

- Choose Diamond Turning if: Your part is round, requires the absolute lowest surface roughness ($R_a < 5nm$), and you need cost-effective production for lenses or mirrors.

- Choose Ultra-Precision Milling if: Your part has non-rotational features, is a lens array, requires sharp corners, or involves complex 3D contours that cannot be spun.

At YISHUN, we do not force your part into a process that doesn’t fit. Our facility is equipped with both world-class Diamond Turning Lathes and 5-Axis Ultra-Precision Milling centers. We analyze your STEP files, evaluate the optical requirements, and select the kinematic approach that yields the highest accuracy at the lowest cycle time.

Ready to validate your optical design?