Absolutely. Precision lapping is one of the most effective industrial processes specifically designed to improve surface finish, achieving exceptionally smooth, flat, and reflective surfaces that other machining methods cannot. This advanced abrasive machining technique removes microscopic amounts of material from a workpiece by using fine abrasive particles suspended in a liquid slurry between the part and a lapping plate. The result is a significant reduction in surface roughness, measured in Ra (Roughness average), leading to enhanced component performance, longevity, and reliability in critical applications.

Table of Contents

- What Exactly is Precision Lapping?

- How Does the Precision Lapping Process Work?

- Quantifying the Improvement: Measuring Surface Finish After Lapping

- Why Choose Lapping? The Key Benefits for Your Components

- How Does Lapping Compare to Other Finishing Methods?

- What Materials and Applications Benefit from Precision Lapping?

- Conclusion: Elevating Component Performance with Precision Lapping

What Exactly is Precision Lapping?

Understanding precision lapping requires looking beyond its superficial resemblance to polishing. It is a highly controlled machining process engineered for supreme accuracy in surface geometry. Unlike methods that primarily focus on aesthetic shine, lapping is fundamentally about creating functionally superior surfaces with defined characteristics of flatness, parallelism, and, most notably, an exceptionally low surface roughness.

Defining Lapping: Beyond Simple Polishing

Lapping is a form of *superfinishing* that utilizes a “three-body abrasive” action. This involves the workpiece, a lapping plate (typically made of soft cast iron or another composite material), and an abrasive slurry. The slurry, a mixture of a liquid carrier (oil or water-based) and fine abrasive particles (such as aluminum oxide, silicon carbide, or diamond), is applied between the plate and the workpiece. As the lapping plate rotates, it causes the loose abrasives to roll and slide against the workpiece, uniformly shearing off microscopic peaks from its surface. This controlled erosion produces a smooth, non-directional, and often matte finish, distinguishing it from the bright, reflective finish of polishing, which often involves smearing or plastic deformation of the surface material.

The “Precision” Factor: Achieving Sub-Micron Tolerances

The term “precision” is integral to modern lapping. It signifies the process’s ability to achieve incredibly tight and repeatable dimensional and geometric tolerances, often on a sub-micron scale. Precision lapping machines allow for meticulous control over variables such as pressure, plate speed, and the type and size of the abrasive particles. This control enables engineers to remove material with extreme predictability, correcting minute imperfections in flatness and achieving surface finishes that are often impossible with traditional grinding or milling. The goal isn’t just a smooth surface, but a *geometrically perfect* surface that meets stringent engineering specifications.

How Does the Precision Lapping Process Work?

The effectiveness of precision lapping in refining surface finish stems from its unique and highly controllable mechanical process. It’s a systematic method of material removal that relies on the interaction of three key elements to produce surfaces with unparalleled flatness and smoothness. By understanding this mechanism, one can appreciate why it is the preferred method for high-stakes applications.

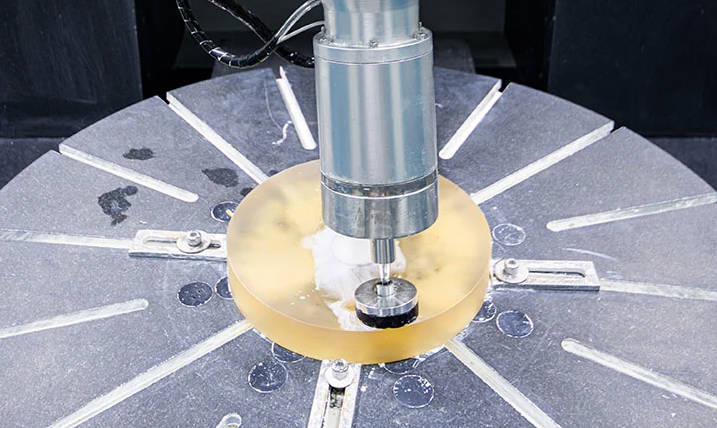

The Three Core Components: Lapping Plate, Abrasive Slurry, and Workpiece

At the heart of the lapping process are its three fundamental components. First is the Lapping Plate, a large, perfectly flat circular disc that acts as the moving datum surface. Its material and design are crucial for holding the abrasive and maintaining its own flatness. Second is the Abrasive Slurry, which contains precisely graded abrasive particles suspended in a liquid. The particle size, concentration, and type of abrasive are selected based on the workpiece material and the desired final finish. Finally, there is the Workpiece itself, which is held against the rotating plate, often within conditioning rings or carriers that help maintain plate flatness and guide the part’s movement.

The Mechanism of Material Removal: A Controlled Abrasive Action

The magic of lapping happens at the microscopic level. As the lapping plate rotates, the workpieces are moved across its surface in an oscillating or planetary motion. The abrasive particles in the slurry become trapped between the plate and the workpiece. These particles then roll and slide, acting as tiny cutting tools that shear away the high points (peaks or asperities) of the workpiece’s surface. This process is gentle and uniform, avoiding the deep scratches and subsurface damage associated with fixed-abrasive methods like grinding. The material is removed layer by layer, gradually reducing the surface roughness and converging the workpiece’s geometry towards that of the ultra-flat lapping plate.

Single-Sided vs. Double-Sided Lapping: Which is Right for Your Component?

Lapping processes can be categorized into two main types: single-sided and double-sided. Single-sided lapping involves finishing one surface of a component at a time. It is ideal for parts where only one face is critical or for components with irregular shapes that cannot be easily held for double-sided processing. Double-sided lapping, on the other hand, machines the top and bottom surfaces of a component simultaneously. Parts are placed in carriers that rotate between two opposing lapping plates. This method is exceptionally efficient and is the gold standard for achieving not only excellent surface finish but also superior parallelism and thickness control on flat, parallel components like semiconductor wafers, optical windows, and precision spacers.

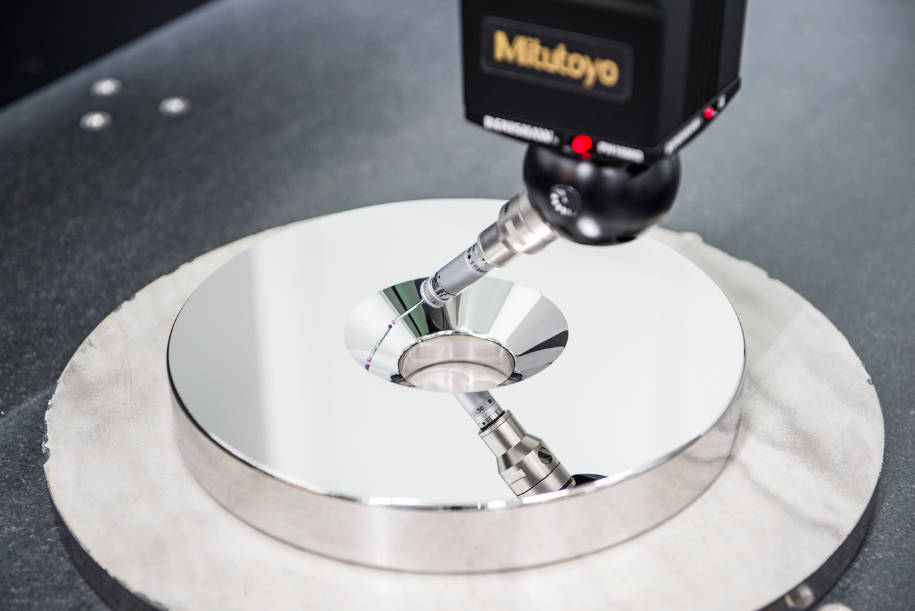

Quantifying the Improvement: Measuring Surface Finish After Lapping

The primary goal of precision lapping is to drastically improve surface finish, and this improvement is not just subjective—it is a measurable, quantifiable enhancement. To appreciate the value of lapping, it’s essential to understand the standard metrics used to define surface texture and the typical results that can be expected from the process.

Understanding Surface Finish Metrics: Ra, Rz, and Rq

Surface finish is typically quantified using a profilometer, which measures the microscopic peaks and valleys on a surface. The most common parameter is Ra (Roughness Average), which represents the arithmetic average of the absolute values of the profile height deviations from the mean line. It provides a general description of the surface texture. For more detailed analysis, other parameters are used:

- Rz (Average Maximum Height of the Profile): This measures the average distance between the highest peak and the lowest valley within five sampling lengths, making it more sensitive to occasional scratches or defects than Ra.

- Rq (Root Mean Square Roughness): Similar to Ra, but it calculates the root mean square of the profile height deviations. Rq is more sensitive to large peaks and valleys than Ra.

For most industrial applications, a lower Ra value indicates a smoother, more desirable surface finish, which is precisely what lapping delivers.

Typical Surface Finish Values Achievable with Lapping

Precision lapping dramatically reduces Ra values compared to standard machining operations. While a fine-ground surface might have an Ra of 0.4 µm (16 µin), a lapped surface can easily achieve an Ra of 0.025 µm (1 µin) or even lower, approaching a mirror-like state. This level of smoothness is critical for creating effective sealing surfaces, reducing friction and wear, and improving optical clarity.

| Machining Process | Typical Ra (micrometers, µm) | Typical Ra (microinches, µin) | Notes |

|---|---|---|---|

| Milling | 1.6 – 6.3 | 63 – 250 | Rough, visible tool marks. |

| Grinding | 0.4 – 1.6 | 16 – 63 | Good finish, but can induce stress. |

| Precision Lapping | 0.025 – 0.4 | 1 – 16 | Exceptional finish, high flatness. |

| Polishing | < 0.025 | < 1 | Mirror finish, primarily for reflectivity. |

Why Choose Lapping? The Key Benefits for Your Components

While the improvement in surface finish is the most cited advantage, the decision to use precision lapping often involves a suite of interconnected benefits that collectively enhance component quality and performance. These advantages go beyond a simple smooth surface, addressing critical geometric and material properties.

Unmatched Surface Finish and Reflectivity

The primary benefit is, of course, the creation of an ultra-smooth surface. This low-roughness finish is crucial for applications requiring fluid or gas seals, as it eliminates leak paths. For example, in mechanical seals and valve components, a lapped surface ensures a tight, reliable seal under high pressure. In optical applications, a perfectly smooth surface minimizes light scatter, while in tribological systems, it reduces the coefficient of friction, minimizing wear and heat generation between moving parts.

Achieving Exceptional Flatness and Parallelism

Lapping is unparalleled in its ability to generate extreme flatness. The process uses the principle of “averaging,” where the workpiece conforms to the shape of the ultra-flat lapping plate. This corrects bowing, warping, or other deviations from a perfectly flat plane. Tolerances for flatness can be held to within millionths of an inch (or fractions of a lightband). Furthermore, double-sided lapping imparts this flatness to both sides of a component *simultaneously*, ensuring the two surfaces are almost perfectly parallel to each other. This is indispensable for components like gauge blocks, substrates, and precision shims.

Tight Dimensional Control and Consistency

Because lapping removes material at a very slow and predictable rate, it offers exceptional control over the final thickness of a component. This allows for the production of parts with extremely tight dimensional tolerances, batch after batch. The consistency and repeatability of the lapping process mean that every part in a production run will have nearly identical surface finish, flatness, and thickness, ensuring high yields and reliable assembly in complex devices.

Stress-Free Material Removal

High-energy processes like grinding can generate significant heat and mechanical stress, leading to subsurface damage, micro-cracking, and metallurgical changes in the workpiece. Lapping, by contrast, is a low-pressure, low-temperature process. The gentle abrasive action removes material without inducing stress or thermal distortion. This is critically important for delicate materials like crystals and ceramics, or for high-performance metal components where residual stress could lead to premature failure.

How Does Lapping Compare to Other Finishing Methods?

To fully grasp the unique role of precision lapping, it’s helpful to compare it directly with other common surface finishing processes like grinding and polishing. Each method has its own strengths and is suited for different applications and outcomes.

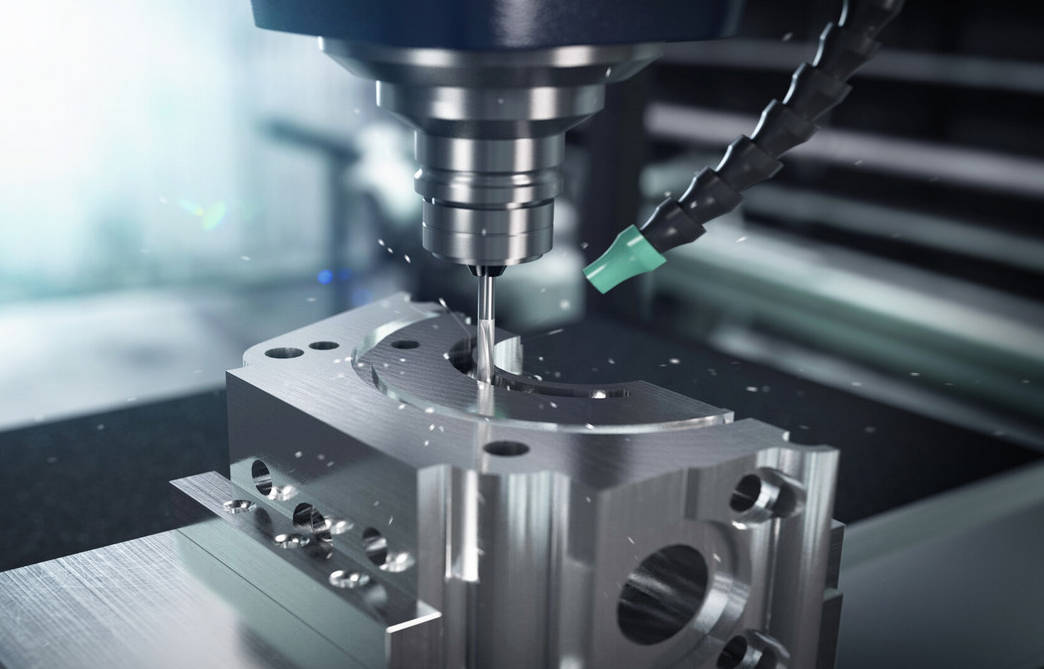

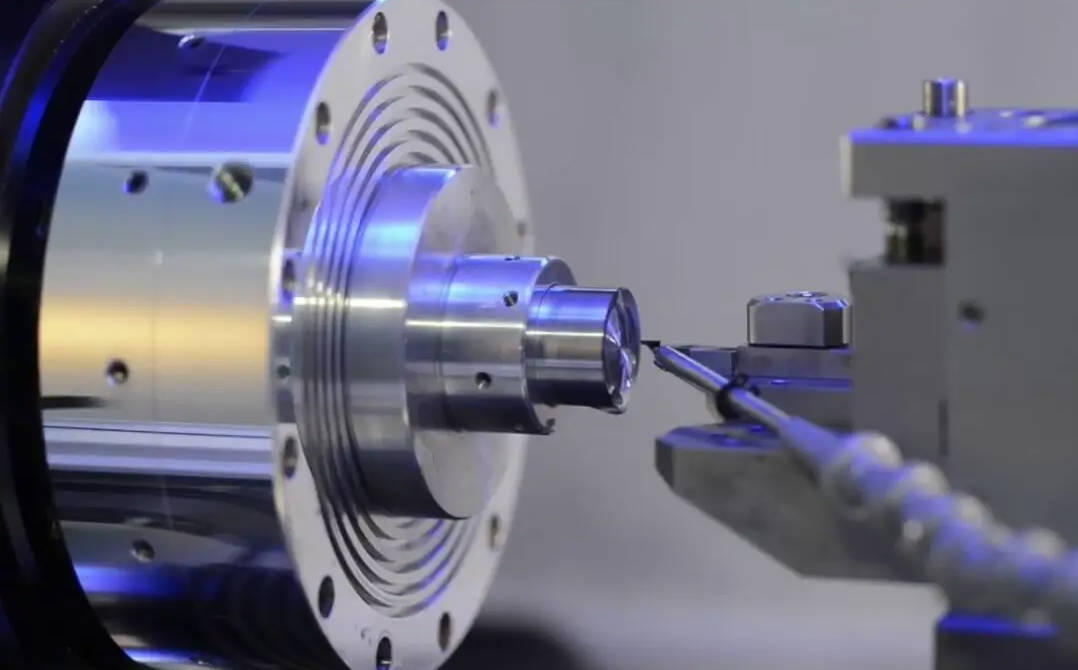

Lapping vs. Grinding: The Difference in Precision and Surface Damage

Grinding is a finishing process that uses a bonded abrasive wheel rotating at high speed to remove material. While it can produce good surface finishes and tight dimensional tolerances, it fundamentally differs from lapping. Grinding is a high-energy process that can induce significant thermal stress and subsurface damage. The fixed abrasives in a grinding wheel create a directional lay or pattern of scratches. In contrast, lapping is a low-stress process that produces a random, non-directional finish with minimal to no subsurface damage. Lapping is used to correct the geometric inaccuracies and surface damage that grinding can leave behind, taking the component to the next level of precision.

Lapping vs. Polishing: A Matter of Flatness vs. Shine

Lapping and polishing are often confused, but they serve different primary purposes. The main objective of lapping is to achieve geometric accuracy—specifically, extreme flatness. While a very smooth finish is a byproduct, the focus is on creating a true plane. Polishing, on the other hand, is primarily aimed at achieving a bright, reflective, mirror-like surface. Polishing typically uses a soft pad (e.g., polyurethane or felt) and extremely fine abrasives. This process tends to round off edges and may not maintain the flatness achieved through lapping. In many high-precision workflows, lapping is the preparatory step performed before polishing to first establish the required flatness and smoothness.

What Materials and Applications Benefit from Precision Lapping?

The versatility and gentle nature of the lapping process make it suitable for an incredibly wide range of materials and critical applications where surface integrity and geometric precision are non-negotiable. Its impact is felt across nearly every high-technology sector.

A Versatile Process for Diverse Materials

One of the key strengths of lapping is its ability to effectively finish almost any material, regardless of its hardness or fragility. By selecting the appropriate lapping plate and abrasive slurry, excellent results can be achieved on:

- Hard Materials: Ceramics (Alumina, Zirconia), Tungsten Carbide, Sapphire, Silicon Nitride.

- Metals: Stainless Steel, Tool Steel, Titanium, Aluminum, Copper, and various alloys.

- Brittle Materials: Silicon, Germanium, Glass, Quartz, and other crystalline materials.

- Plastics and Composites: Although less common, certain stable polymers and composites can also be lapped.

Critical Applications Across High-Tech Industries

The demand for lapped components is driven by the stringent requirements of modern technology. Some of the most common applications include:

- Aerospace & Defense: Components for guidance systems, hydraulic valve plates, and fuel system parts that require perfect seals.

- Medical: Prosthetic implants (like hip and knee joints), surgical tools, and diagnostic equipment parts where biocompatibility and low friction are key.

- Semiconductors: Silicon wafers and other substrates require extreme flatness and a damage-free surface for photolithography.

- Optics & Photonics: Laser mirrors, optical windows, and prisms need lapped surfaces to minimize light distortion and maximize performance.

- Automotive: Mechanical seals for water pumps, fuel injector components, and transmission parts that demand reliability and longevity.

Conclusion: Elevating Component Performance with Precision Lapping

So, can precision lapping improve surface finish? The answer is an unequivocal yes. It is not merely an improvement but a transformation, taking a standard machined surface to a state of exceptional smoothness, flatness, and dimensional accuracy. By employing a controlled, low-stress abrasive action, lapping removes microscopic imperfections to create functionally superior surfaces that are essential for the performance and reliability of today’s most advanced technologies. Whether the goal is creating a perfect seal, reducing friction, or ensuring optical clarity, precision lapping provides a level of surface refinement that stands as a benchmark in modern manufacturing.

Precision Lapping, improve surface finish, surface finish improvement, what is precision lapping, lapping process, lapping vs polishing, surface roughness Ra, benefits of lapping, lapping for flatness, double-sided lapping, mechanical seals, lapping materials