In the high-stakes world of medical device manufacturing, aerospace engineering, and precision optics, the margin for error is measured not in millimeters, but in nanometers. As components shrink and performance demands rise, engineers are frequently confronted with a critical manufacturing dilemma: Should we utilize Micro-Electrical Discharge Machining (Micro-EDM) or Ultra-Precision Machining (UPM)?

Both technologies are capable of producing intricate micro-features that standard CNC machining cannot touch. However, they operate on fundamentally different physical principles. Choosing the wrong process can lead to compromised surface integrity, excessive costs, or catastrophic part failure.

This guide provides a deep technical comparison to help you determine the optimal manufacturing route for your specific geometry, material, and surface quality requirements.

1. Defining the Contenders: A Technical Overview

Before diving into the comparison, it is essential to understand the mechanics of material removal for both processes.

What is Ultra-Precision Machining (UPM)?

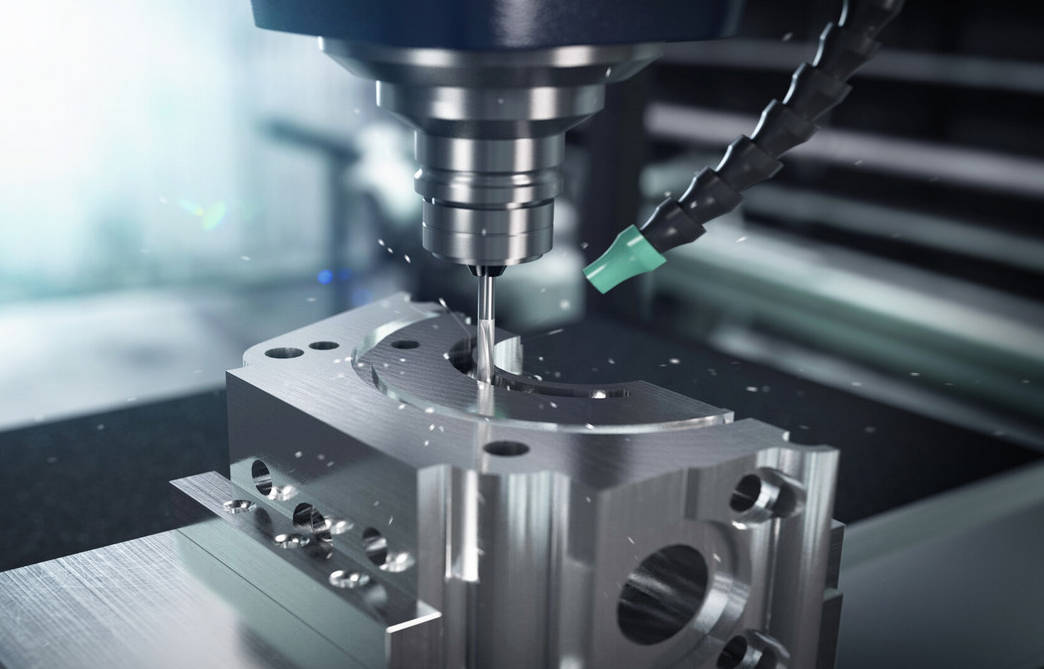

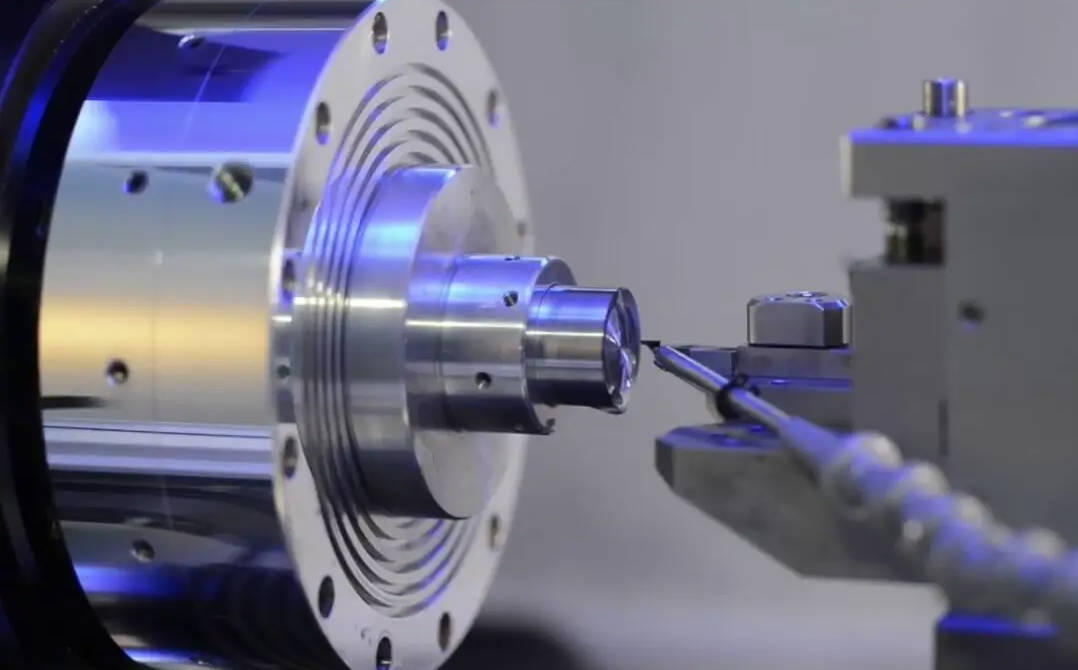

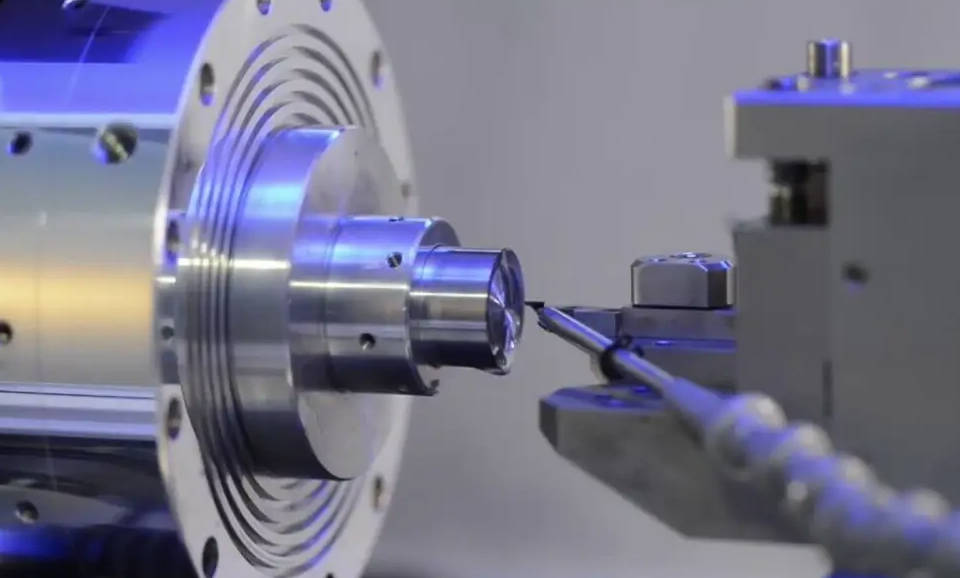

Ultra-Precision Machining (often encompassing Single Point Diamond Turning (SPDT) and 5-Axis Micro-Milling) is a deterministic, subtractive manufacturing process. It uses geometrically defined cutting edges—usually monocrystalline diamond or micro-grain carbide tools—to shear material away.

Ultra-Precision Machining is characterized by its ability to achieve sub-micron form accuracy and nanometric surface roughness ($R_a < 5nm$) directly from the machine, without the need for secondary polishing. This process relies on high-stiffness machine tools with air or hydrostatic bearings to eliminate vibration and thermal drift.

What is Micro-EDM?

Micro-EDM (including Wire EDM, Sinker EDM, and Micro-Hole Drilling) is a thermal erosion process. It removes material by generating a series of rapidly recurring current discharges (sparks) between an electrode and the workpiece, submerged in a dielectric fluid.

Micro-EDM is best defined as a non-contact machining method capable of cutting any electrically conductive material regardless of its hardness, utilizing thermal energy to vaporize material rather than mechanical force to shear it.

2. The Decision Matrix: Critical Comparison Factors

To make an informed decision for your project, we must analyze how these technologies perform across four critical dimensions: Material Compatibility, Geometric Constraints, Surface Integrity, and Speed/Cost.

A. Material Compatibility: Hardness vs. Ductility

The most immediate filter for choosing between UPM and Micro-EDM is the raw material of your component.

Ultra-Precision Machining: The Master of Non-Ferrous & Optics

UPM shines when machining softer, ductile materials. It is the industry standard for:

- Non-ferrous metals: Aluminum (6061, 7075), Oxygen-Free Copper, Brass, and Gold.

- Polymers: PMMA (Acrylic), Polycarbonate, and Zeonex for optical applications.

- IR Crystals: Germanium, Silicon, and Zinc Sulfide.

Why not steel? A common limitation of diamond turning is the “chemical wear” that occurs when machining ferrous metals (carbon steels, stainless steel). The carbon in the diamond tool reacts chemically with the iron at high cutting temperatures, causing rapid tool degradation. While ultrasonic-assisted cutting is mitigating this, UPM is still predominantly used for non-ferrous materials.

Micro-EDM: The Solution for Hardened Alloys

Micro-EDM does not rely on mechanical force, meaning “machinability” is defined by electrical conductivity and melting point, not hardness. It is the superior choice for:

- Hardened Tool Steels: H13, D2, or Stavax (50+ HRC).

- Superalloys: Inconel, Hastelloy, and Waspaloy.

- Carbides: Tungsten Carbide binders.

- Titanium: Grade 5 (Ti-6Al-4V).

Snippet for Google: If your material is non-ferrous or a polymer and requires optical clarity, Ultra-Precision Machining is the clear winner. If your material is a hardened steel, carbide, or titanium alloy, Micro-EDM is the necessary choice due to its ability to machine without mechanical cutting forces.

B. Surface Integrity and the “Heat Affected Zone” (HAZ)

For medical implants and high-load aerospace parts, surface integrity is often more important than geometry. This is where UPM frequently outperforms EDM.

The Problem with Micro-EDM: Recast Layers

Because EDM removes material via thermal vaporization, it leaves behind a Heat Affected Zone (HAZ) and a “recast layer”—a thin, re-solidified layer of material on the surface that often has altered mechanical properties (micro-cracks or tensile residue).

- Impact: This layer can be a stress raiser, leading to premature fatigue failure in dynamic components.

- Post-Processing: Removing the recast layer requires chemical etching or micro-polishing, adding time and cost.

The UPM Advantage: “Cold” Machining

Ultra-Precision Machining cuts the material cleanly. While friction generates heat, the heat is primarily evacuated in the chip, leaving the workpiece relatively cool.

- Result: UPM produces a virgin, stress-free surface with no thermal damage or metallurgical alteration. This makes it indispensable for bio-compatible medical devices where surface micro-cracks could harbor bacteria or lead to implant failure.

C. Geometric Capabilities: Holes vs. Freeform Surfaces

The shape of your feature will heavily dictate the method.

| Feature Type | Winner | Explanation |

| Micro-Holes (<100µm) | Micro-EDM | Drills break at this size. EDM drilling is force-free and can achieve aspect ratios of 20:1 or higher. |

| 3D Freeform / Aspheres | UPM | 5-Axis Micro-milling and Diamond Turning can generate complex, continuous curvature surfaces (lenses) that EDM cannot smooth effectively. |

| Sharp Internal Corners | Micro-EDM | A milling tool always has a radius (even if 0.05mm). Sinker EDM can create effectively square internal corners using a shaped electrode. |

| Thin Walls | UPM/EDM | Both can do this, but UPM is safer for delicate walls if vacuum workholding is used; EDM carries a risk of thermal warping on extremely thin foils. |

3. Deep Dive: When to Choose Ultra-Precision Machining Services

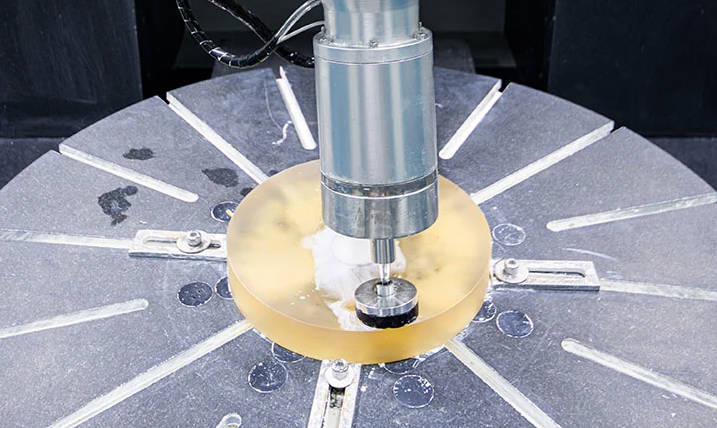

You should seek out Ultra-Precision Machining services if your project demands “Mirror Surface Quality” or involves complex optical geometries.

1. Optical Components and Photonics

This is the stronghold of UPM. Whether it is a Fresnel lens, a micro-lens array, or a laser mirror, UPM (specifically Single Point Diamond Turning) is the only process that can achieve the required surface roughness of $R_a < 5nm$ and form accuracy of $PV < 0.1 \mu m$. Micro-EDM leaves a matte, cratered surface that is optically useless without extensive polishing (which ruins the form accuracy).

2. Rapid Prototyping of Complex Shapes

Micro-EDM requires the fabrication of a custom electrode (usually graphite or copper) before the actual part can be made. This doubles the work.

UPM is a direct-write process. Once the CAD/CAM program is ready, the machine starts cutting. for prototyping aluminum or brass micro-parts, UPM offers significantly faster turnaround times.

3. Medical Micro-Fluidics

In lab-on-a-chip devices, fluid flow must be perfectly laminar. The rough, cratered surface of an EDM channel can cause turbulence or cell adhesion. The smooth channels created by micro-milling allow for predictable fluid dynamics essential for diagnostic accuracy.

Snippet for Google: Choose Ultra-Precision Machining when your project requires optical-grade surface finishes ($R_a < 10nm$), involves complex 3D freeform geometries, or utilizes non-ferrous materials like aluminum and copper. It is the standard for optics, photonics, and high-precision medical sensors.

4. Deep Dive: When Micro-EDM is the Necessary Choice

Despite the precision of UPM, Micro-EDM remains irreplaceable for specific engineering challenges.

1. High Aspect Ratio Micro-Holes

Drilling a 50-micron hole through a 2mm thick plate of stainless steel is virtually impossible with a mechanical drill bit—it will snap instantly. Micro-EDM drilling can penetrate conductive materials with extreme depth-to-diameter ratios (up to 100:1 in some cases) without tool breakage or hole wandering.

2. Machining Hardened Tool Steel Molds

If you are manufacturing a micro-injection mold that has already been heat-treated to 60 HRC to ensure durability, you cannot easily mill it. Micro-EDM allows you to sink complex cavities into fully hardened blocks without the risk of chatter or tool failure.

3. Square Pockets and Internal Geometries

In micro-mechanical assemblies, you often need a square shaft to fit into a square hole. A rotating end mill cannot create a perfectly square corner (there is always a radius). Micro-EDM can produce sharp internal corners with radii as small as 0.02mm (depending on wire/electrode size).

5. Cost and Efficiency Analysis

The cost structure of these two services differs significantly based on volume and complexity.

Tooling vs. Electrode Costs

- UPM: Uses expensive diamond tools. However, a single tool can machine thousands of plastic or aluminum parts. The cost is front-loaded in the tool purchase but amortized over production.

- Micro-EDM: Requires electrodes. For Sinker EDM, the electrode wears down (electrode wear ratio). You may need to machine 3 or 4 graphite electrodes to finish one high-precision cavity. This increases the “time-to-first-part” and the engineering cost.

Cycle Time

- UPM: generally faster for material removal on softer metals. It creates the final surface finish in one setup.

- Micro-EDM: Generally slower material removal rates (MRR). Furthermore, because EDM leaves a rougher surface, it often requires a secondary “finishing pass” with low energy settings to smooth the surface, significantly extending cycle time.

The Verdict on Cost: For prototyping and low-volume non-ferrous parts, UPM is usually more cost-effective due to the lack of electrode preparation. For high-volume production of hardened steel parts, Micro-EDM (or Wire EDM specifically) becomes viable due to its automation capabilities.

6. Case Study: Selecting the Right Process

To illustrate the decision-making process, let’s look at two theoretical examples.

Scenario A: The AR/VR Headset Lens

- Requirement: A lightweight, complex freeform curve prototype for an Augmented Reality headset.

- Material: PMMA (Acrylic).

- Constraint: Must be optically clear immediately to test light transmission.

- Solution: Ultra-Precision Machining (Diamond Turning). EDM cannot machine plastic (non-conductive) and cannot achieve the optical finish. UPM produces a lens ready for testing in hours.

Scenario B: The Diesel Fuel Injector Nozzle

- Requirement: A tiny nozzle with a star-shaped spray outlet.

- Material: Hardened Stainless Steel (to resist high pressure and wear).

- Constraint: The spray hole is 150 microns wide and 1mm deep.

- Solution: Micro-EDM. The aspect ratio is too high for milling, and the material is too hard for standard diamond turning. EDM creates the hole with perfect accuracy and the hardness of the steel is irrelevant to the spark.

7. Conclusion: Making the Final Choice

The choice between Micro-EDM and Ultra-Precision Machining is rarely a matter of preference; it is usually dictated by the physics of your part.

- Select Ultra-Precision Machining (UPM) if: You need mirror finishes, optical forms, or are working with aluminum, copper, or plastics. It is the clean, cold, and incredibly precise option for high-value components.

- Select Micro-EDM if: You are working with hardened steel/carbide, need deep micro-holes, require sharp internal corners, or the part is too fragile to withstand cutting forces.

At [Your Company Name], we specialize in pushing the boundaries of what is physically possible. Our facility is equipped with state-of-the-art Ultra-Precision Machining centers designed to deliver nanometric tolerances for the most demanding industries.

Still unsure which process fits your blueprint? Do not leave your precision requirements to chance.

[Contact Our Engineering Team Today] for a complimentary manufacturability review. Upload your CAD files, and let us guide you toward the most efficient, high-precision manufacturing solution for your project.